Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-15 Origin: Site

When selecting glass materials for products ranging from kitchen appliances to architectural elements, understanding the difference between ceramic glass and regular glass is crucial. Both materials might look similar at first glance, but their properties and ideal applications differ significantly. At NAF GLASS, a manufacturer with over 20 years of expertise in glass production, we strive to provide clarity on these differences so our customers can make well-informed decisions tailored to their needs. Knowing what distinguishes ceramic glass will help you choose a product that offers durability, safety, and aesthetic appeal suited to your specific requirements.

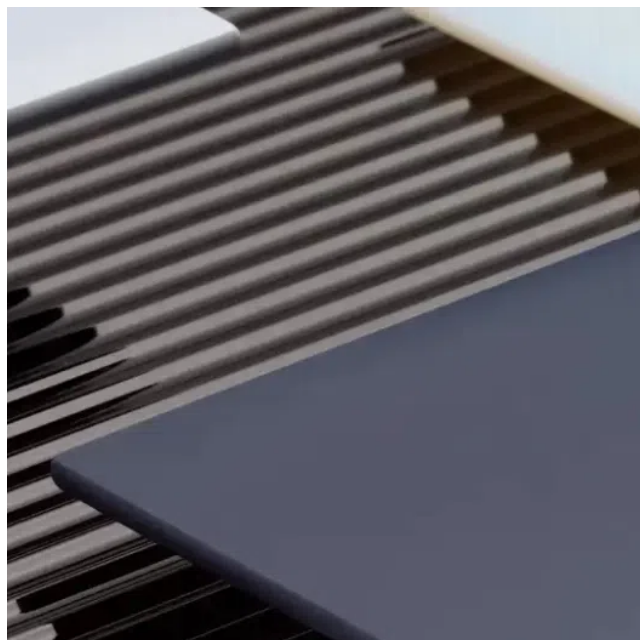

Ceramic glass is produced through a controlled crystallization process, which forms microscopic ceramic crystals within a glass matrix. This unique structure combines the thermal and mechanical strengths of ceramics with the transparency and smoothness of glass. Unlike regular glass, commonly made via soda-lime or float glass techniques, ceramic glass undergoes precise heat treatments that stabilize its internal microstructure.

This advanced manufacturing method results in a hybrid material that is highly resistant to temperature changes, mechanical stress, and chemical corrosion. Regular glass lacks these crystalline reinforcements, making it more vulnerable to thermal shock, scratches, and chemical damage. The difference in composition explains why ceramic glass can excel in environments where regular glass would fail or require frequent replacement.

One of the most significant distinctions between ceramic glass and regular glass is their capacity to endure heat. Ceramic glass can withstand continuous temperatures of up to approximately 800°C (1470°F) without deforming or losing structural integrity. It also tolerates sudden temperature changes—thermal shocks—of over 400°C (750°F), making it ideal for applications involving rapid heating and cooling cycles.

Such exceptional heat resistance makes ceramic glass suitable for use in cooktops, oven doors, fireplace panels, and industrial furnaces where traditional glass would easily crack or shatter. The ability to maintain stability under extreme thermal conditions also enhances safety in domestic and industrial settings, reducing the risk of accidents caused by glass failure.

In contrast, regular glass typically withstands heat up to only around 200°C (390°F). Exceeding this limit can lead to softening, warping, or breaking. Sudden temperature fluctuations pose even greater risks, as standard glass lacks the structural reinforcement to manage thermal stress. This limitation confines regular glass to low-temperature applications such as windows or decorative elements where heat exposure is minimal.

Mechanical strength and scratch resistance represent another area where ceramic glass outperforms regular glass. Ceramic glass rates between 7 and 8 on the Mohs hardness scale, making it highly resistant to surface scratches, impacts, and abrasion. This hardness ensures that products like stovetops or laboratory equipment maintain a pristine appearance and functional integrity over long periods, even under heavy use.

Regular glass, while relatively sturdy, has a Mohs hardness rating of about 5.5, meaning it scratches and chips more easily. Frequent contact with utensils, cleaning tools, or accidental impacts can damage its surface, potentially compromising both safety and aesthetics. Over time, scratched or chipped glass may also harbor bacteria or stains, which complicates maintenance.

Choosing ceramic glass guarantees enhanced durability, lower maintenance needs, and improved lifespan, especially in environments prone to physical wear.

The chemical inertness of ceramic glass adds further value, especially in environments exposed to harsh substances. Thanks to its non-porous, chemically stable surface, ceramic glass resists staining, corrosion, and degradation when in contact with acids, alkalis, or organic solvents. This property makes it a top choice for laboratory apparatus, sterilization equipment, and kitchen surfaces where exposure to chemicals is common.

Regular glass, although chemically stable under normal conditions, can react adversely to prolonged contact with strong chemicals or cleaning agents. Its surface might develop stains, etching, or micro-fractures that reduce transparency and structural integrity. This susceptibility demands careful maintenance and limits its application in chemically aggressive settings.

Ceramic glass’s chemical resistance ensures that surfaces remain clean and functional without frequent replacements or special treatments.

Aesthetic considerations also differentiate ceramic glass from regular glass. Ceramic glass is available in a variety of thicknesses and finishes, including translucent, opaque, matte, and decorative patterned options. Translucent versions provide soft light diffusion, adding a subtle design element while maintaining functional advantages such as heat resistance.

Regular glass offers excellent clarity and transparency and comes in numerous decorative styles as well. However, it lacks the ability to combine advanced mechanical and thermal properties with diverse aesthetic options in the same way ceramic glass does. For customers requiring both durability and style—especially in architectural or appliance designs—ceramic glass presents a compelling choice.

Additionally, ceramic glass can be customized with edge detailing, cutouts, and coatings without compromising its structural benefits, making it a versatile material for designers and engineers alike.

Knowing where each glass type excels allows you to make better purchasing decisions. Ceramic glass is indispensable in high-heat, high-wear, or chemically demanding environments. Common applications include induction cooktops, oven doors, fireplace panels, industrial furnaces, fire-rated windows, and medical or laboratory devices.

Regular glass remains suitable for general-purpose uses where extreme performance is not necessary, such as residential windows, furniture glass, picture frames, or decorative panels exposed to moderate conditions. Its lower cost and ease of production make it a practical choice for these areas.

Choosing ceramic glass in the right context provides long-term benefits including improved safety, longevity, and user satisfaction, which ultimately lead to cost savings and fewer replacements.

Understanding the differences between ceramic glass and regular glass is vital for selecting the appropriate material for your application. Ceramic glass offers superior heat resistance, mechanical durability, and chemical stability that regular glass cannot match. At NAF GLASS, we are proud to offer high-quality ceramic glass products engineered to meet diverse industrial and residential needs with exceptional performance and reliability.

For expert guidance on choosing the right glass for your project or to explore our full range of ceramic glass solutions, please contact us today. Our experienced team is here to support you every step of the way.