Please Choose Your Language

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-20 Origin: Site

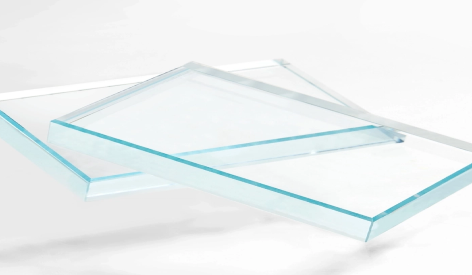

In the world of modern architecture, design, and high-performance building materials, glass plays an essential role. Among the various types available on the market, one specific kind stands out for its remarkable clarity, quality, and versatility—Ultra Clear Float Glass.

Whether you're designing a high-end storefront, a luxury residential façade, or a museum-grade display case, Ultra Clear Float Glass offers a level of performance and aesthetic quality that standard glass cannot match.

Ultra Clear Float Glass, sometimes referred to as low-iron float glass or crystal clear glass, is a high-transparency float glass with extremely low iron content. The reduced iron oxide in the raw materials used during the float process eliminates the greenish tint typically found in ordinary clear float glass. This results in an exceptionally clear and color-neutral glass that allows for maximum light transmittance and true color presentation.

Unlike conventional glass, which may distort colors or appear slightly green under certain lighting conditions, Ultra Clear Float Glass maintains a bright and true appearance even in thicker formats.

The manufacturing process of Ultra Clear Float Glass is similar to that of standard float glass, but with one critical difference—the raw materials used are carefully selected and processed to remove iron impurities. Here’s a simplified breakdown of the process:

Raw Material Selection: High-purity silica sand, soda ash, dolomite, and limestone are chosen for their low iron content.

Melting: These materials are melted in a furnace at temperatures exceeding 1500°C.

Float Process: The molten glass is poured onto a bed of molten tin. It spreads and flattens out into a uniform sheet, forming a smooth and flat surface.

Annealing: The glass is slowly cooled in a controlled environment to relieve internal stresses and ensure durability.

Cutting and Inspection: After cooling, the glass is cut into sheets of various sizes and undergoes quality inspection.

The result is a premium float glass that offers superior optical performance and enhanced aesthetic appeal.

Ultra Clear Float Glass is prized for its unique properties. Here are the most significant features:

With iron content significantly lower than ordinary glass, Ultra Clear Float Glass transmits up to 91% of visible light. This makes it ideal for applications requiring natural lighting and visibility, such as storefronts, skylights, and greenhouses.

Thanks to its low iron content, Ultra Clear Float Glass does not distort or absorb the colors of objects seen through it. This makes it perfect for museums, galleries, and high-end retail stores.

The float manufacturing process ensures a uniform thickness and flatness, minimizing optical distortion. This is essential in applications like architectural glazing and optical instruments.

The absence of a greenish tint allows Ultra Clear Float Glass to blend seamlessly into modern design schemes. It offers a crisp, clean, and luxurious appearance.

Ultra Clear Float Glass can be further treated with Low-E coatings, lamination, tempering, or silk-screen printing to enhance thermal insulation, safety, or decorative performance.

The versatility of Ultra Clear Float Glass lends itself to a wide range of applications across industries:

Curtain Walls: Provides a high-end look for modern glass façades.

Canopies and Skylights: Allows for abundant daylight while maintaining structural strength.

Balustrades and Railings: Combines safety with unobstructed views.

Ultra Clear Float Glass offers exceptional transparency and minimal green tint, making it ideal for various interior design uses:

Partitions and Doors: Enhances natural light flow and creates a clean, modern look. Its high clarity maintains visual openness in offices, homes, and commercial spaces without color distortion.

Shower Enclosures: Provides a premium, crystal-clear finish that showcases bathroom materials accurately. It helps create a bright, spa-like atmosphere and can be coated to resist water spots.

Tabletops and Furniture: Perfect for glass tabletops, shelves, and cabinet doors, allowing the beauty of underlying materials to shine through without distortion. Its polished edges add safety and elegance to luxury furnishings.

Showcases and Cabinets: Ideal for museums, boutiques, and galleries where color fidelity is important.

Jewelry and Watch Displays: Highlights products without any green hue or distortion.

Its high transparency and low iron content make Ultra Clear Float Glass a favored choice for photovoltaic panels and greenhouse glazing, helping to maximize energy efficiency and plant growth.

Ultra Clear Glass is used in specialty vehicle windows and transportation displays where visibility and safety are critical.

Choosing Ultra Clear Float Glass over regular glass may come with a slightly higher cost, but the benefits far outweigh the initial investment:

Energy Savings: When combined with Low-E coatings, it significantly improves insulation and reduces heating/cooling costs.

Design Flexibility: It complements any style, from minimalist to classic, without interfering with the intended color schemes.

Sustainability: Many manufacturers offer recyclable options, contributing to green building certifications.

Property Value Boost: High-end finishes like Ultra Clear Glass add tangible value to both residential and commercial properties.

Customer Perception: For retail environments, clarity enhances product visibility, encouraging customer trust and purchases.

Feature | Standard Clear Glass | Ultra Clear Float Glass |

Iron Content | Higher | Significantly Lower |

Color Tint | Greenish | Color-Neutral |

Light Transmittance | ~84-87% | ~91% |

Visual Clarity | Moderate | Exceptional |

Cost | Lower | Higher, but premium |

This side-by-side comparison makes it evident why Ultra Clear Float Glass is the preferred choice for projects that demand performance and prestige.

Before selecting Ultra Clear Float Glass for your project, consider the following factors.

Glass Thickness: Choose the appropriate thickness based on structural requirements.

Edge Treatment: Decide between raw-cut, polished, or beveled edges for safety and aesthetics.

Coating Options: Determine if additional coatings like Low-E or anti-reflective layers are necessary.

Size Availability: Ensure the supplier can meet your custom dimension requirements.

As energy efficiency, transparency, and aesthetics become top priorities in modern construction and design, Ultra Clear Float Glass emerges as a leading material that meets and exceeds expectations. Its low-iron composition offers unmatched clarity and performance, making it ideal for both functional and decorative applications.

Whether you're working on a residential renovation or a large-scale commercial build, selecting the right type of glass can make all the difference in energy savings, visual appeal, and overall user experience.

For architects, designers, and developers looking for high-performance Ultra Clear Float Glass, Qingdao NAF Glass Industries Co., Ltd. offers a range of products engineered to meet the highest standards. With years of experience, advanced production lines, and a commitment to quality, they are a trusted partner in glass innovation.

If you’re ready to take your project to the next level, we invite you to explore more about Ultra Clear Float Glass and how it can be tailored to your needs by reaching out to Qingdao NAF Glass Industries Co., Ltd. for product specifications and expert advice.